Properties of Arsenic–Doped ZnTe Thin Films as a Back Contact for CdTe Solar Cells

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Properties of As-Doped Polycrystalline (px) ZnTe Thin Films by MOCVD

3.2. Device Incorporation of ZnTe:As to CdTe Thin Film Solar Cells

3.3. Optimisation of ZnTe:As BCL to CdTe Thin Film Solar Cells

Cl-Free H2 Annealing

3.4. ZnTe:As BCL Thickness Optimisation

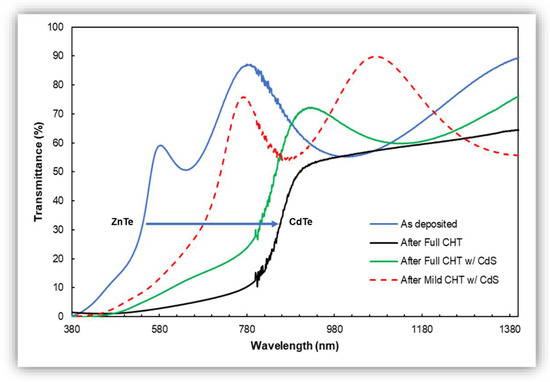

3.5. Cl-Annealing BCL Post-Deposition Treatments

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Green, M.A.; Emery, K.; Hishikawa, Y.; Warta, W.; Dunlop, E.D. Solar cell efficiency tables (version 50). Prog. Photovolt. Res. Appl. 2017, 25, 668–676. [Google Scholar] [CrossRef] [Green Version]

- Lourenço, M.A.; Yew, Y.K.; Homewood, K.P.; Durose, K.; Richter, H.; Bonnet, D. Deep level transient spectroscopy of CdS/CdTe thin film solar cells. J. Appl. Phys. 1997, 82, 1423–1426. [Google Scholar] [CrossRef]

- Amin, N.; Yamada, A.; Konagai, M. Effect of ZnTe and CdZnTe Alloys at the Back Contact of 1-µm-Thick CdTe Thin Film Solar Cells. Jpn. J. Appl. Phys. 2002, 41, 2834–2841. [Google Scholar] [CrossRef]

- Bätzner, D.L.; Romeo, A.; Zogg, H.; Wendt, R.; Tiwari, A.N. Development of efficient and stable back contacts on CdTe/CdS solar cells. Thin Solid Films 2001, 387, 151–154. [Google Scholar] [CrossRef]

- Irvine, S.J.C.; Barrioz, V.; Lamb, D.; Jones, E.W.; Rowlands-Jones, R.L. MOCVD of thin film photovoltaic solar cells—Next generation production technology? J. Cryst. Growth 2008, 330, 5198–5203. [Google Scholar] [CrossRef]

- Späth, B.; Fritsche, J.; Klein, A.; Jaegermann, W. Nitrogen doping of ZnTe and its influence on CdTe/ZnTe interfaces. Appl. Phys. Lett. 2007, 90, 062112. [Google Scholar] [CrossRef]

- Li, J.; Beach, J.D.; Wolden, C.A. Rapid Thermal Processing of ZnTe:Cu Contacted CdTe Solar Cells. In Proceedings of the 40th IEEE Photovoltaic Specialist Conference, Denver, CO, USA, 8–13 June 2014; pp. 2360–2365. [Google Scholar]

- Uliĉnâ, S.; Isherwood, P.J.M.; Kaminski, P.M.; Walls, J.M.; Li, J.; Wolden, C.A. Development of ZnTe as back contact material for thin film cadmium telluride solar cells. Vacuum 2016, 139, 159–163. [Google Scholar] [CrossRef]

- Amin, N.; Yamada, A.; Konagai, M. ZnTe Insertion at the Back Contact of 1 µm-CdTe Thin Film Solar Cells. In Proceedings of the 28th IEEE Photovoltaic Specialists Conference, Anchorage, AK, USA, 15–22 September 2000; pp. 650–653. [Google Scholar]

- Makhratchev, K.; Price, K.J.; Ma, X.; Simmons, D.A.; Drayton, J.; Ludwig, K.; Gupta, A.; Bohn, R.G.; Compaan, A.D. ZnTe:N Back Contacts to CdS/CdTe Solar Cells. In Proceedings of the 28th IEEE Photovoltaic Specialists Conference, Anchorage, AK, USA, 15–22 September 2000; pp. 475–478. [Google Scholar]

- Kartopu, G.; Oklobia, O.; Turkay, D.; Diercks, D.R.; Gorman, B.P.; Barrioz, V.; Campbell, S.; Major, J.D.; Al Turkestani, M.K.; Yerci, S.; et al. Study of thin film poly-crystalline CdTe solar cells presenting high acceptor concentrations achieved by in-situ arsenic doping. Sol. Energy Mater. Sol. Cells 2019, 194, 259–267. [Google Scholar] [CrossRef]

- Kamata, A.; Yoshida, H. Highly conductive p-type ZnTe: As grown by atmospheric metalorganic chemical vapor deposition using Trimethylarsine. Jpn. J. Appl. Phys. 1996, 35, CL87–CL89. [Google Scholar] [CrossRef]

- Turco-Sandroff, F.S.; Brasil, M.J.S.P.; Nahory, R.E.; Martin, R.J.; Zhang, T.; Skromme, B.J. Arsenic-doped P-type ZnTe grown by molecular beam epitaxy. Appl. Phys. Lett. 1991, 59, 688–690. [Google Scholar] [CrossRef]

- Mohanty, D.; Su, P.-Y.; Wang, G.-C.; Lu, T.-M.; Bhat, I.B. Effect of CdCl2 treatment on ZnTe back electron reflector layer in thin film CdTe solar cells. Sol. Energy 2016, 135, 209–214. [Google Scholar] [CrossRef]

- Shimpi, T.M.; Swanson, D.E.; Drayton, J.; Abbas, A.; Walls, J.M.; Barth, K.L.; Sampath, W.S. CdS barrier to minimize Zn loss during CdCl2 treatment of Cd-Zn-Te absorbers. Sol. Energy 2018, 173, 1181–1188. [Google Scholar] [CrossRef]

- Kartopu, G.; Philips, L.J.; Barrioz, V.; Irvine, S.J.C.; Tejedor, E.; Dupin, D.; Clayton, A.J.; Rugen-Hankey, S.L.; Durose, K. Progression of metalorganic chemical vapour-deposited CdTe thin-film PV devices towards modules. Prog. Photovolt. Res. Appl. 2016, 283–291. [Google Scholar] [CrossRef]

- Becker, J.J.; Campbell, C.M.; Zhao, Y.; Boccard, M.; Mohanty, D.; Lassise, M.; Suarez, E.; Bhat, I.; Holman, Z.C.; Zhang, Y.-H. Monocrystalline CdTe/MgCdTe Double-Heterostructure Solar Cells with ZnTe Hole Contacts. IEEE J. Photovolt. 2017, 7, 307–312. [Google Scholar] [CrossRef]

- Shimpi, T.M.; Drayton, J.; Swanson, D.E.; Sampath, W.S. Properties of Nitrogen-doped Zinc Telluride Films for Back Contact to Cadmium Telluride Photovoltaics. J. Electron. Mater. 2017, 46, 5112–5120. [Google Scholar] [CrossRef]

- Okamoto, T.; Yamada, A.; Konagai, M. Characterization of Highly Efficient CdTe Thin Film Solar Cells by the Capacitance-Voltage Profiling Technique. Jpn. J. Appl. Phys. 2000, 39, 2587–2588. [Google Scholar] [CrossRef]

- Maniscalo, B.; Abbas, A.; Bowers, J.W.; Kaminski, P.M.; Bass, K.; West, G.; Walls, J.M. The activation of thin film CdTe solar cells using alternative chlorine containing compounds. Thin Film Solids 2015, 582, 115–119. [Google Scholar] [CrossRef]

- Tobin, S.P.; Norton, P.W.; Chandler-Horowitz, D.; Amirtharaj, P.M.; Lope, V.C.; Duncan, W.M.; Syllaios, A.J.; Ard, C.K.; Giles, N.C.; Lee, J.; et al. A Comparison of Techniques for Nondestructive Composition Measurements in CdZnTe Substrates. J. Electron. Mater. 1995, 24, 697–705. [Google Scholar] [CrossRef]

- Wolden, C.A.; Abbas, A.; Li, J.; Diercks, D.R.; Meysing, D.M.; Ohno, T.R.; Beach, J.D.; Barnes, T.M.; Walls, J.M. The roles of ZnTe buffer layers on CdTe solar cell performance. Sol. Energy Mater. Sol. Cells 2016, 147, 203–210. [Google Scholar] [CrossRef] [Green Version]

- Abbas, A.; West, G.D.; Bowers, J.W.; Kaminski, P.M.; Maniscalco, B.; Walls, J.M.; Barth, K.L.; Sampath, W.S. Cadmium Chloride Assisted Re-Crystallisation of CdTe: The Effect of Annealing Over-Treatment. In Proceedings of the IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA; 2014; pp. 701–706. [Google Scholar]

- Reich, C.L.; Swanson, D.E.; Onno, A.; Shimpi, T.; Metzger, W.K.; Sampath, W.S.; Holman, Z.C. Alloy Loss Mitigation Through Use of Barrier Layers During CdCl2 Processing of Cd0.60Zn0.4Te and Cd0.87Mg0.13Te. In Proceedings of the IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC), Waikoloa, HI, USA, 10–15 June 2018. [Google Scholar]

| As (sccm) | Bandgap (eV) | Bulk concentration (cm−3) | Mobility (cm2/V·s) | Resistivity (Ω·cm) | Conductivity (S/cm) |

|---|---|---|---|---|---|

| 0 | 2.23 | - | - | - | - |

| 1 | 2.24 | - | - | 2.93 × 104 | 3.41 × 10−5 |

| 3 | 2.21 | 5.33 × 1017 | 7.54 × 10−2 | 1.55 × 102 | 6.45 × 10−3 |

| 5 | 2.20 | 1.11 × 1018 | 2.74 × 10−1 | 2.14 × 101 | 4.68 × 10−2 |

| 10 | 2.19 | 4.50 × 1018 | 8.48 × 10−1 | 1.63 × 100 | 6.14 × 10−1 |

| ZnTe:As (nm) | η (%) | JSC (mA/cm2) | VOC (V) | FF (%) | RS (Ωcm2) | NA (cm−3) | Wd (µm) |

|---|---|---|---|---|---|---|---|

| 50 | 10.4 | 23.3 | 0.689 | 65 | 5.00 | 1.7 × 1015 | 1.01 |

| 100 | 11.9 | 23.7 | 0.696 | 72 | 1.45 | 1.9 × 1015 | 0.96 |

| 200 | 11.8 | 24.1 | 0.691 | 71 | 1.62 | 3.2 × 1015 | 0.78 |

| 330 | 11.7 | 24.1 | 0.701 | 69 | 1.69 | 2.0 × 1015 | 0.81 |

| Element | No Mild CHT | Mild CHT | Mild CHT w/CdS |

|---|---|---|---|

| Zn (at %) | 39.0 | 16.3 | 26.5 |

| Cd (at %) | 4.6 | 31.8 | 24.8 |

| Te (at %) | 56.4 | 51.9 | 48.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oklobia, O.; Kartopu, G.; J. C. Irvine, S. Properties of Arsenic–Doped ZnTe Thin Films as a Back Contact for CdTe Solar Cells. Materials 2019, 12, 3706. https://doi.org/10.3390/ma12223706

Oklobia O, Kartopu G, J. C. Irvine S. Properties of Arsenic–Doped ZnTe Thin Films as a Back Contact for CdTe Solar Cells. Materials. 2019; 12(22):3706. https://doi.org/10.3390/ma12223706

Chicago/Turabian StyleOklobia, Ochai, Giray Kartopu, and Stuart J. C. Irvine. 2019. "Properties of Arsenic–Doped ZnTe Thin Films as a Back Contact for CdTe Solar Cells" Materials 12, no. 22: 3706. https://doi.org/10.3390/ma12223706